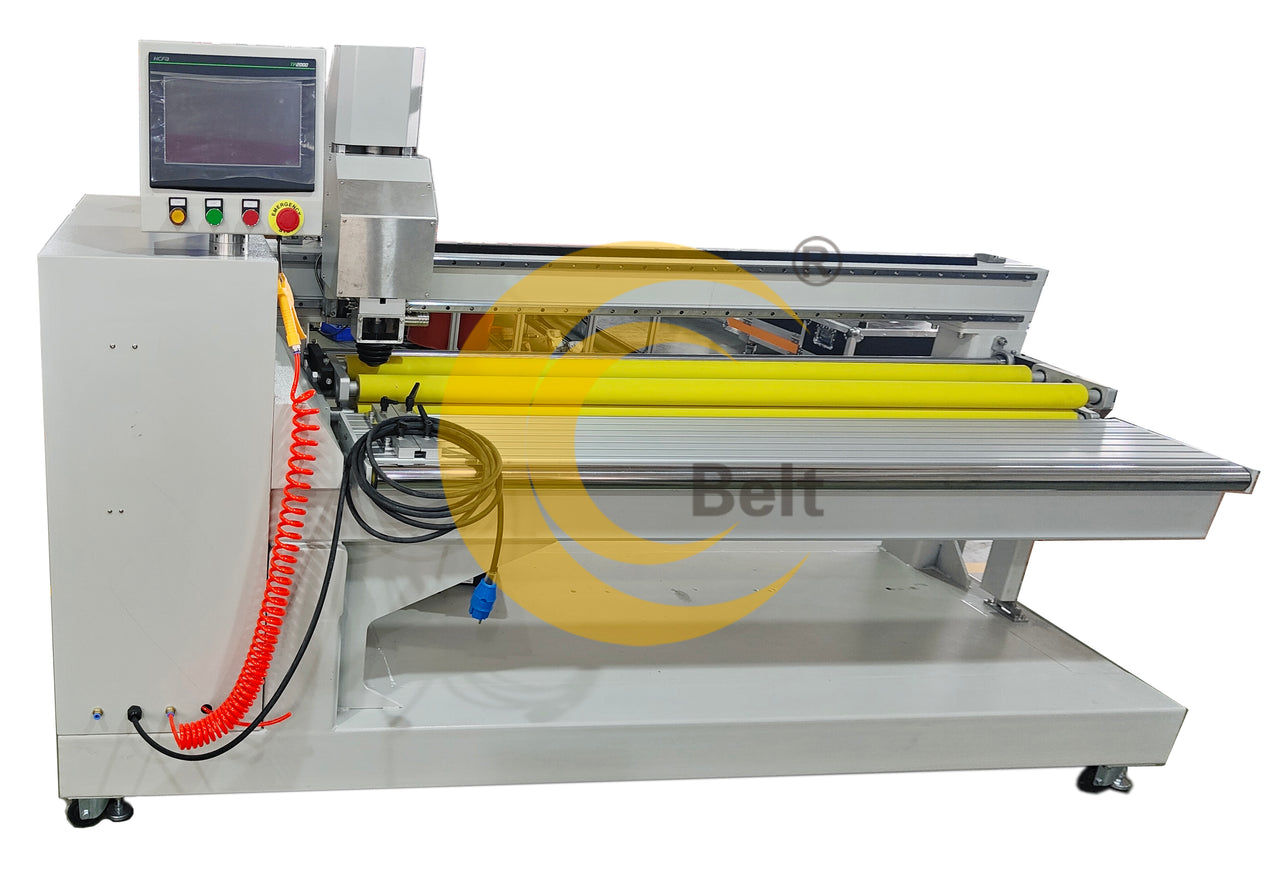

The Conveyor Belt Perforating Machine is designed for high-precision hole punching in TPU, PVC, and transmission belts, enabling improved airflow, vacuum grip, and specialized purposes including vacuuming, drying, water/liquid drainage, sorting/filtration of goods, and mounting hardware or profiles.

Engineered for accuracy and efficiency, this machine ensures clean, uniform perforations while maintaining belt integrity.

Custom colors, thicknesses, profiles and special features available upon request, please contact us for more information.

| Model | KCB-PF1000 | KCB-PF1600 | KCB-PF2000 | KCB-PF3200 |

| Power | 3.5 KW | |||

| Motor | 4 x 750W servo motors | |||

| Voltage | Single-phase 220V | |||

| Air Pressure | 0.5 MPa | |||

| Supported Belts | TPU/PVC/Transmission belts | |||

| Belt Width | ≤900mm | ≤1500mm | ≤1900mm | ≤3100mm |

| Min. Belt Thickness | 1mm | |||

| Max. Belt Thickness | 10mm (15mm for Rubber-Belt-Enhanced Model) | |||

| Perforating Speed | Up to 1.5 punches/second (affected by hole spacing and etc.) | |||

| Perforating Size | φ2-φ20mm (provided with 3 standard sizes (φ2-φ15) | |||

| Min Belt Circumference | 800mm | |||

| Dust Collector | 1800W dust collector included | |||

| Minimum Error | 1mm/1000mm (error can be calibrated with built-in software) | |||

| Net Weight | 815kg | 915kg | 1015kg | 1300kg |

| Dimension | 1950*1000*1600 | 2450*1000*1600 | 2950*1000*1600 | 4050*1000*1600 |

| Accessories | 1x toolbox, 1x PE pad, 2x wrenches, 2x chucks, 2x top pins, 1x 3mm T-wrench, 1x 24mm open-end wrench | |||

Thanks for subscribing!

This email has been registered!