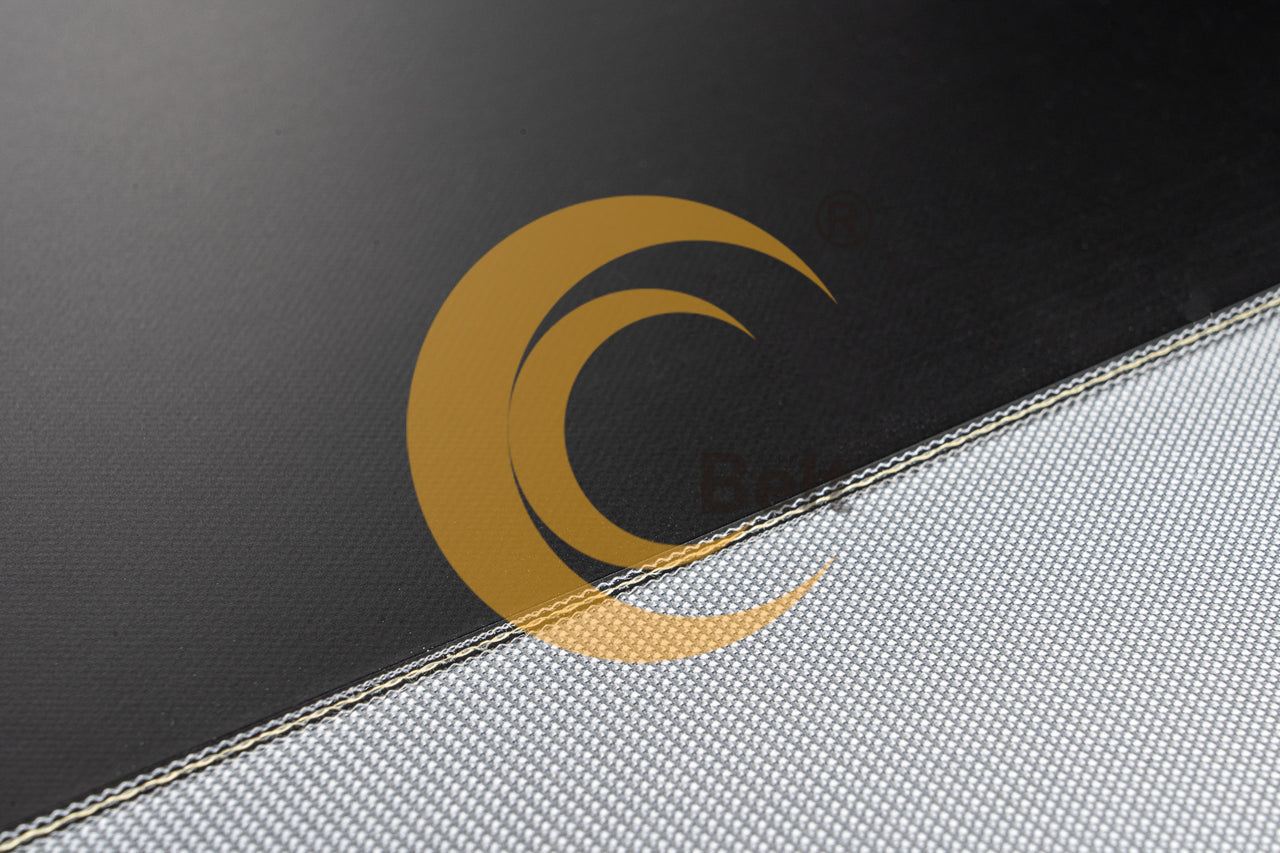

Designed with smooth and even surface to prevent any possible printing deviations, Kevlar® Reinforced carcass layers, improvided mateiral makeup and stability to stand up to attack from dyes or other chemicals, and avoid any speed variation that causes printing alignment errors.

Custom colors, thicknesses, profiles and special features available upon request, please contact us for more information.

| TYPE # | |

| KEM500/3:0+0.5M/2.6BPU | |

| REFERENCE # | |

| ENU-20ELBD Print 6488-2.65E |

|

| GENERAL CHARACTERISTICS: | |

| ROTARY TEXTILE PRINTING | |

| Flat-bed SCREEN PRINTING | |

| TECHNICAL CHARACTERISTICS : | |

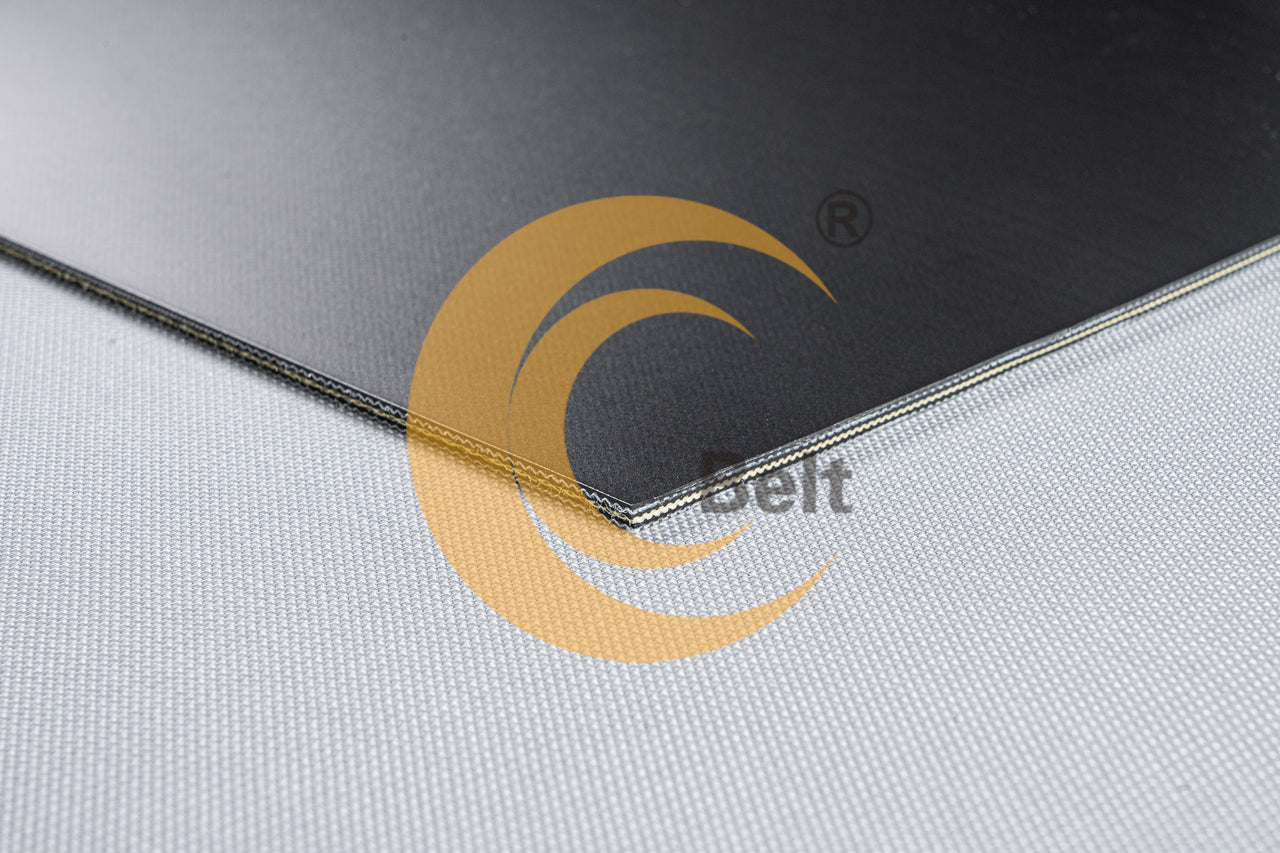

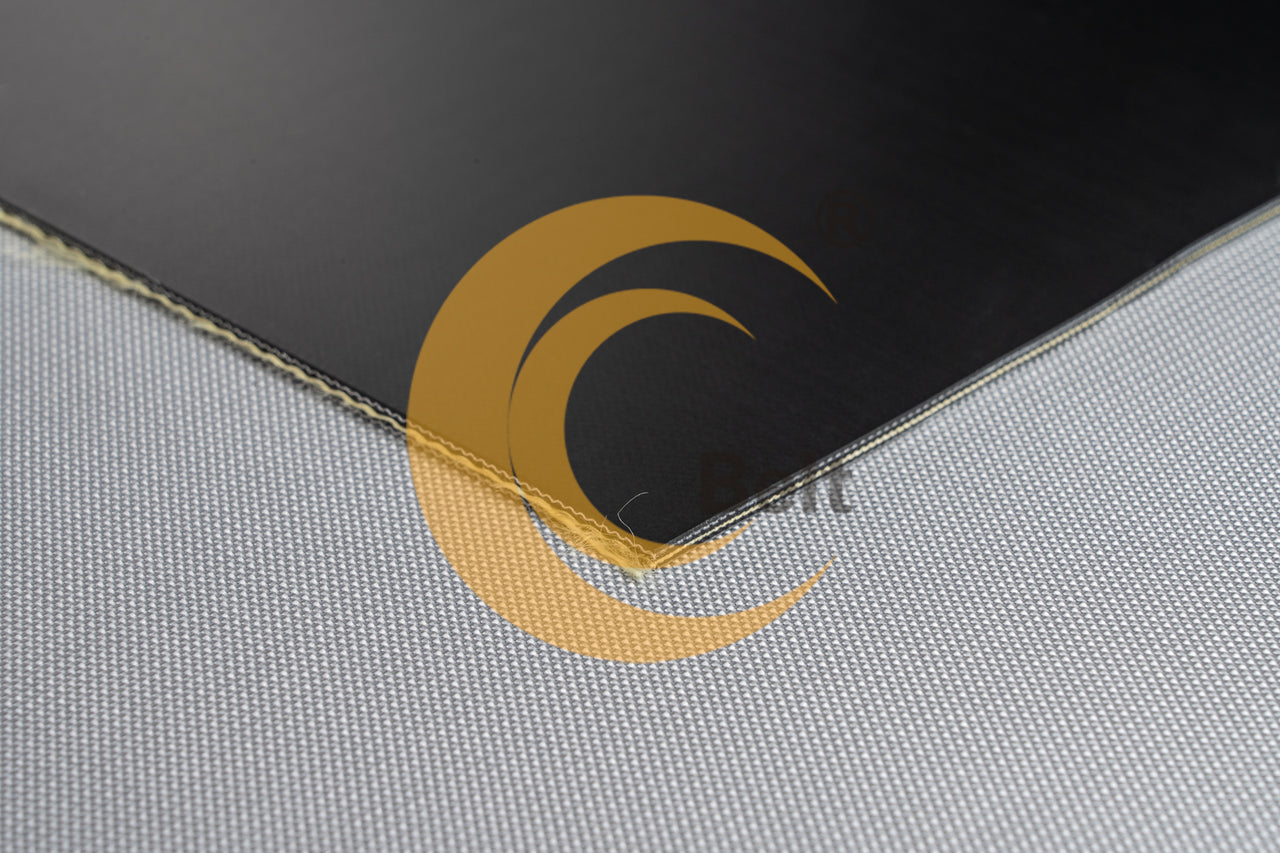

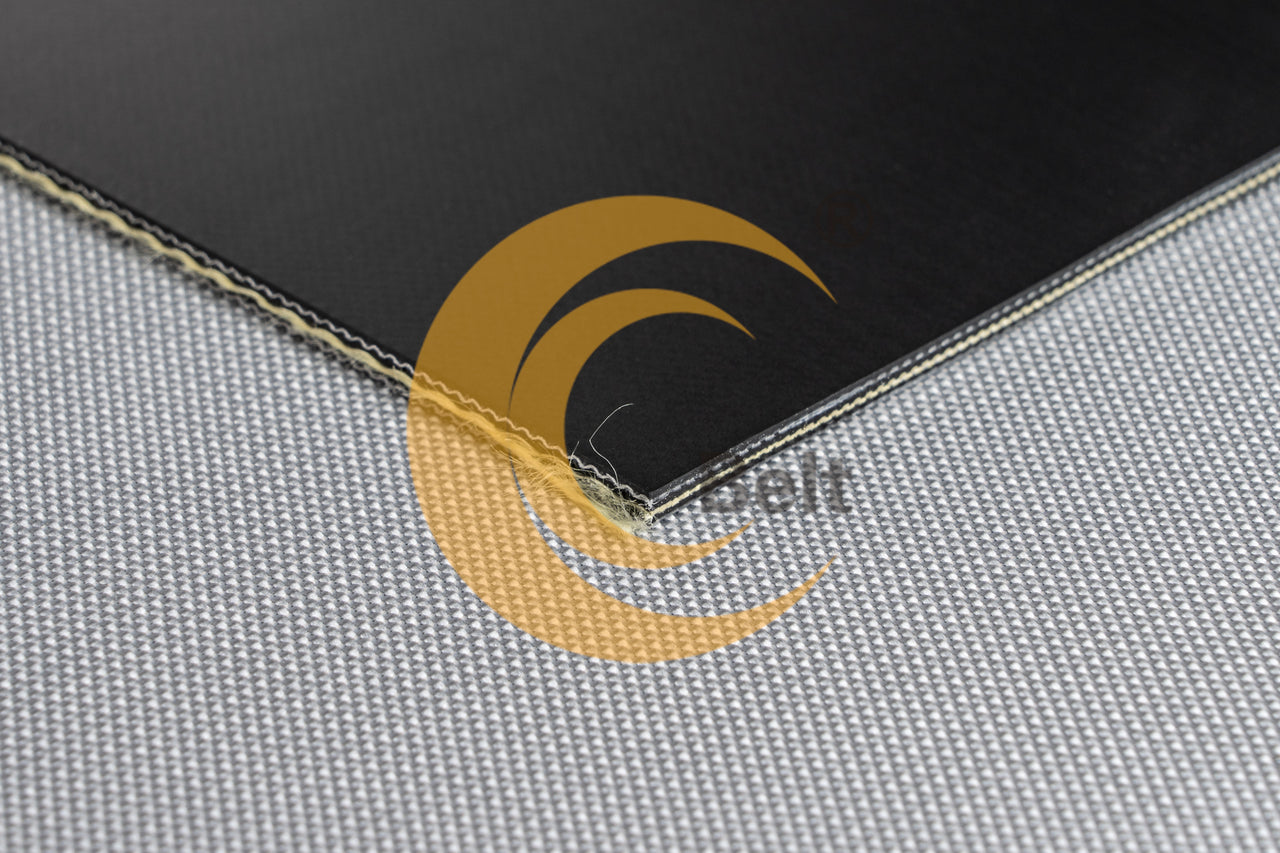

| Total Thickness | 2.6 mm |

| No. of Plies | 3 |

| Fabric | Kevlar + Polyester |

| Weft | Rigid |

| Weight | 2.9 kg(s)/㎡ |

| Working Temperatures | -10 ºC to + 70 ºc |

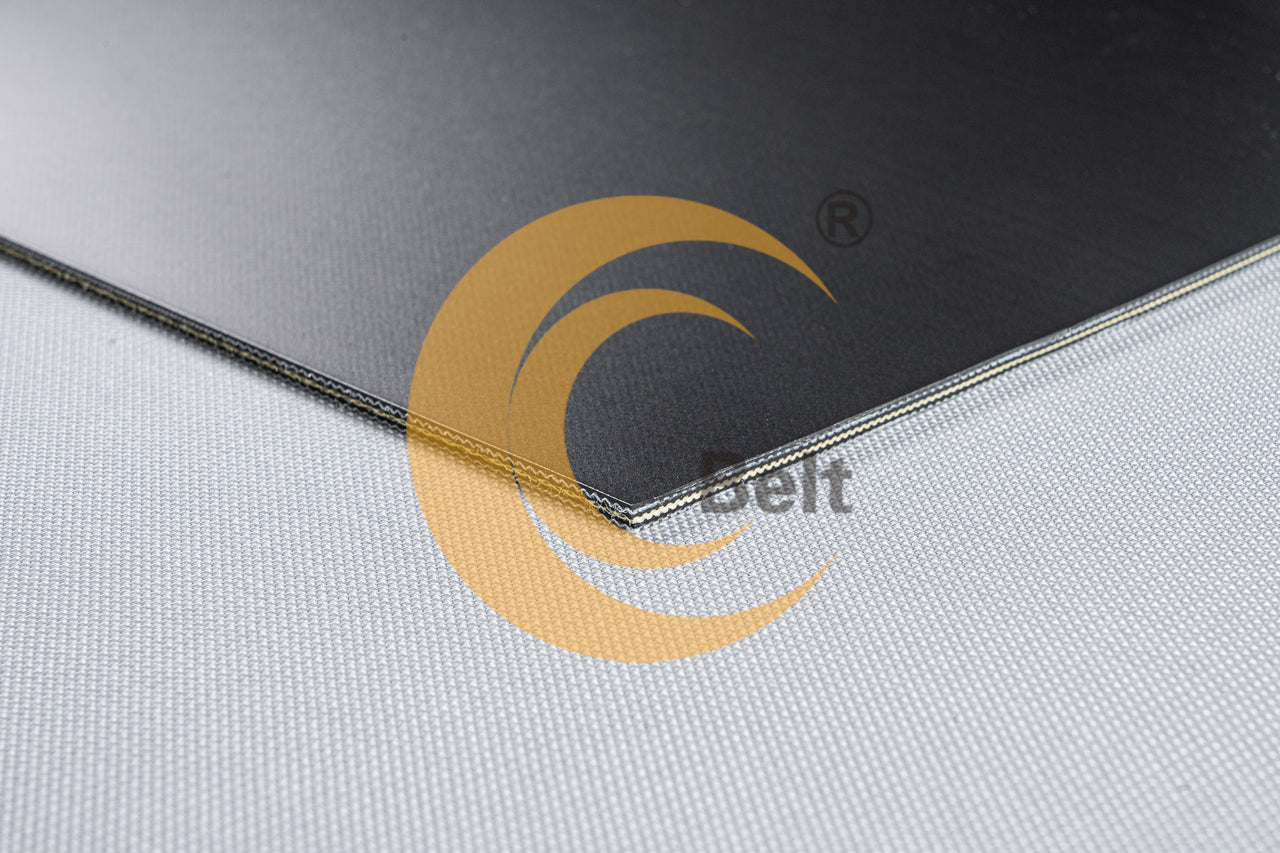

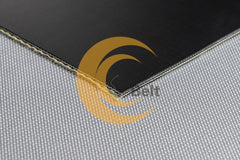

| 1. Top cover | |

| Thickness | 0.5 mm |

| Material | TPU |

| Color | Black (B) |

| Surface | Matt |

| Hardness | 93 ShA |

| 2. Internal layer(s) | |

| Material | TPU |

| Color | Black (B) |

| Fabric | Kevlar |

| 3. Bottom cover | |

| Thickness | - |

| Material | - |

| Color | Natural |

| Surface | Fabric with Impregnation |

| Hardness | - |

| Anti-static Yarn | - |

| BELT TENSION: | |

| Tensile Strength(N/mm) | 500 |

| Max. Suggested Load(N/mm) | 60 |

| Working Load 1% Elongation(N/mm) | 70 |

| FRICTION COEFFICIENTS ON: | |

| Smooth Stainless Steel | 0.16 |

| REMARKS | |

| Max. Manufacturing Width | 4000mm |

| Standard Width | 2000mm, 3000mm |

| MINIMUM PULLEY DIAMETERS: | |

| Front Flexing | 100 mm |

| Back Flexing | 120 mm |

| CONVEYOR FRAME: | |

| Horizontal Rollers | Yes |

| Slider bed | Yes |

| Troughed application | No |

| SPECIAL CHARACTERISTICS: | |

| Food Grade | No |

| Oil Resistant | Yes |

| Flame Retardant | No |

| Surface Antistatic | No |

| Cold Resistant | No |

| JOINING INSTRUCTIONS: | |

| Finger Joint | Step Joint |

| Welding Temperature(°C) | 160 °C ± 10 °C |

| Pressure | 2 bar |

| Cooling | Cool Immediately |

Thanks for subscribing!

This email has been registered!